Quality Inspection for PE PP WPC decking extrusion moulds - WPC Floor Board Mould – Weilei

Quality Inspection for PE PP WPC decking extrusion moulds - WPC Floor Board Mould – Weilei Detail:

|

Name |

WPC FLOOR BOARD MOULD |

|

Size |

Customized |

|

Cavity |

Single-layer |

|

Plastic Material |

WPC |

|

Main application |

WPC floor board, WPC board, etc. |

|

Thickness |

3-8 mm |

|

Product Type |

WPC Floor Board, WPC Board |

|

Mould Guarantee |

1 year |

|

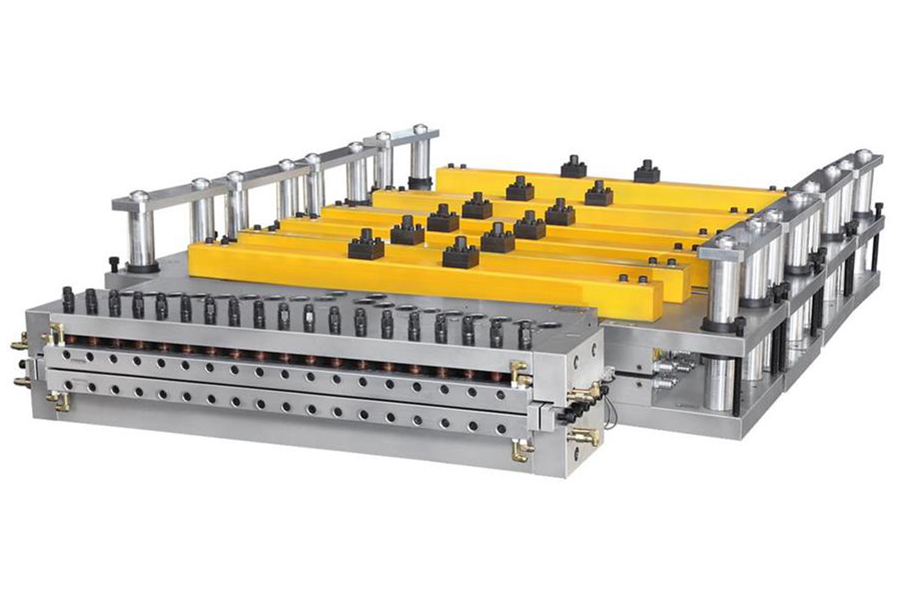

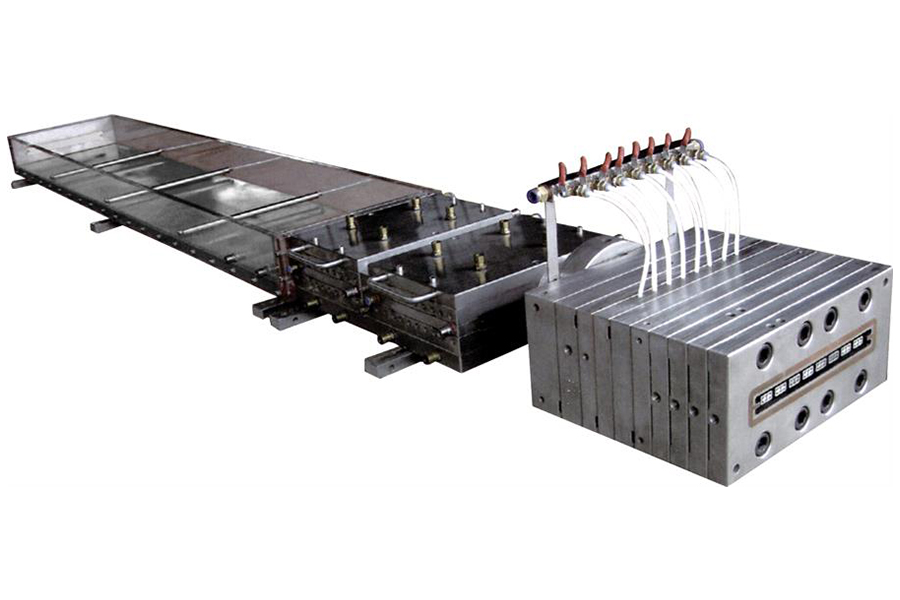

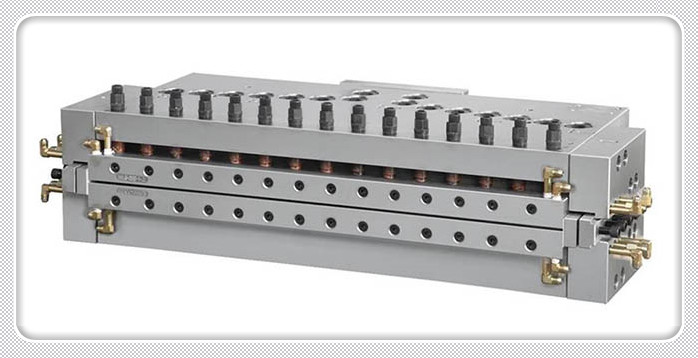

Mould Component |

Die head, heating rod, Flange |

|

The Production Cycle |

30-45 days |

|

Surface Treatment |

Polish |

|

Package & deliver: |

Wood case for exporting, each mould will be cleaned before packing. |

1. Interchange die lip is tor big range thickness, operation is very easy and convenient.

2. Quick lip gap can be adjusted within t 2mm range. Fast Lip Gap adjustment operation is quickly and efficiently and save materials.

3. The layer has Independent temperature control unit and heat insulation device.

4. Automatic Control Die for making Sheet. It can help to reduce the tuning time and defect loss greatly.

5. The product has excellent acid resistance, corrosion resistance, weather resistance and high temperature resistance.

6. Guarantee mold life as per SPI standard or customer specified.

7. Affordable price, high cost performance, stable performance.

8. According to customer needs, design and manufactures for the specifications extrusion die.

Product detail pictures:

Related Product Guide:

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Quality Inspection for PE PP WPC decking extrusion moulds - WPC Floor Board Mould – Weilei , The product will supply to all over the world, such as: Rotterdam, Mombasa, Gabon, With its rich manufacturing experience, high-quality products, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,